Walking down the street it is quite possible that you come across local shops, food chains, cafes and restaurants that sell dishes made out of chicken. But have you ever wondered what happens to those feathers after butchering?

This particular story starts with one of the most fundamental but the most important aspect of the design process – ‘Design thinking’. Back in 2010 when Mr. Radhesh went on to do his masters in design, he was quite blank to begin with, even after having studied bachelors in design. But what came in handy in paving the way ahead was the knowledge of design thinking.

He started his thought process all the way with galaxy – planets – earth – all living things – needs of those living things – humans – needs of humans – basic needs of humans – the most basic need – food – veg & non-veg food – waste out of them – vegetarian waste – non-vegetarian waste. He states that the moment he looked at the waste generated out of the non-veg food, the first thing that came to his mind was chicken. And he asked himself this question – ‘what happens to the feather extracted out of their skin’? That question was worth millions, he didn’t know it back then. He remembers that during his college days, he got a classroom project to ‘convert any waste into a utility product’. He felt that there was an opportunity for him to challenge himself. The same evening, he was visiting a butchery shop to buy chicken and realized that 1 Kg chicken gets only 650 gm of meat and rest is a waste thrown into the gutter or landfill with no further use. He decided then and there to do his project on this waste.

Problem Identification

Life took a different turn since Mr. Radhesh had asked himself that question. Curiosity had taken him to various places in search of the answer he was looking for He got to know that the last time somebody had worked on chicken feather was back in the 18th century. Since then, nobody has worked on this material. He also read about the death of at least 10 people working with chicken feathers due to bird flu. That definitely terrified him for a moment in moving further ahead. Because that would mean going back to figuring out a new problem all over again so that a new material to work with could be identified. But that didn’t deter his enthusiasm in understanding the problem well and deeply. Further knowledge led him to know that those deaths were due to poultry chicken waste. Within 8-9 hours the chicken waste starts to decompose leading to symptoms of bird flu and many other diseases. Later after 24 hours very toxic gases like sulphur dioxide and methane starts to form in that waste which are harmful. We are all aware of the froth formation in Yamuna River near Delhi and how toxic the water has become due to such waste dumping. But what calmed his anxious mind was the information that those deaths were due to poultry chickens. Those chickens were never vaccinated and hence it caused such deadly diseases, while he was trying to work with butchery chicken waste where the chickens are vaccinated before they are shipped to different shops & stores. He identified that there were three types of chicken butchery shops in India – frozen meat shops, chicken markets, and small shops, but their problem of dumping the garbage remains the same causing air pollution, water pollution, flu, and other health hazards.

EXTRACTION OF RAW MATERIAL & PROCESSING

After preliminary research he developed a good understanding of the chicken eating population, based on which he segregated the area of feather collection. He recalls that; shopkeepers would laugh at him when he asked for the feathers. They would ask him what was he going to do with these dirty, blood soaked and smelly feathers? “I didn’t know how to explain it to them back then as I was exploring myself”, he says. It was a difficult job and everything was at a very nascent stage. But those shopkeepers were quite happy because his company had solved their problem by collecting the garbage directly from them. Yet there was way too much to work upon and everything was in the middle of nowhere. He had no idea about how to remove stains? How to make feathers smell free? And he was still figuring out what kind of products could be made out of chicken feathers? These were again the most important questions running in his head for which he had no immediate and concrete answers

He went on great lengths in figuring out the right way of doing the entire work process of collecting wings from the local poultry slaughter house as a raw material to hygienically cleaning & sanitizing them before Feathers are extracted. He came to know that there are four different kinds of feathers on chicken. These feathers are converted into Pulp to create Yarn for handloom Cloth. He said that he had to study so many books on fibers, fabrics, feathers and even chemistry to a great length to figure out how to process this material properly. It was a long and tiring research to carry out.

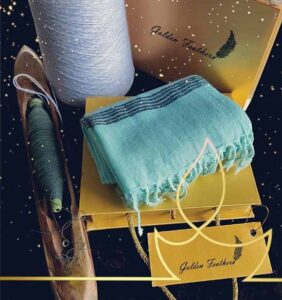

FIBER TO FABRIC

Initially when he started working with the chicken feather, he kept all the feathers (big or small) together in the same basket. That was used to make carpets. But after certain observation he realized that there are different kinds of feathers in different parts of their body. That would also mean they could be used differently and it gave him the idea to find out the best spinnable quality of feather. Hence the spinnable feathers were getting converted into yarn and non-spinnable ones were used for making feather wool. He also recalls his research on the age-old wet-spinning technique which is no longer being practiced by the craftsmen. He used this technique to create one of the finest yarn possible of 1/95 count, even finer than pashmina and more stronger. It was a single ply yarn made out of wet-spinning. This yarn, after weaving, he said, could be easily washed in the washing machine without damaging the fabric. But to reach this stage he had to work for years on research, numerous trying & testing and more than 25 different processes to get the final outcome. He even went on to study about the mummy and the fabric used to wrap it so that he could understand his fabric better. All that effort finally made his feathers smell free, shiny and soft to be used in the long run. He says his feathers can stay upto 60 long years without being damaged. In 2015 with lots of research & experimentation he made yarn from this chicken Fiber and later on set the yarn on the Handloom and converted it into fabric. Today it is known as the 6th natural woolen fiber that is 10 times warmer, softer and durable than any other man-made or natural woolen Fiber. And by the time he converted his feathers into fabrics, he already knew 72 possible products that could be made out of this wonderful material.

SOCIETY, PEOPLE & ENVIRONMENT

Making yarn was the first step towards all the work that needed to be done ahead. He traveled to the remotest places of Rajasthan in search of the suitable manpower. On the way he came across tribal women who would work all day long in the sun only to get 50-60 rupees out of selling wood. These Tribal weavers of Asnawar village were migrating to other areas for work due to the introduction of the power loom. He got those women together and started to provide continuous work and support and a double of the pay. To generate continuous sustainable livelihood for Tribal women in remote Tribal areas of Rajasthan, India by converting Butchery Chicken Waste (BCW) into Handloom Cloth was a fulfilling experience, he says. This project is not only innovative but is also benefiting tribal people of Asnawar village, ragpickers, and butchers. It enables sustainable development, reduction in Environmental pollution & health hazards. Moreover, all those women were able to work comfortably now, at one place, on a daily basis, without worrying about next day work. And it’ll continue to do so, since this yarn can only be hand spun due to its fineness. A staple length of 55 mm and 150 gsm is minimum for a machine to work, while this yarn was of 111 gsm and there is no machine invented yet to work with this fine quality yarn. Developing a new craft was the best thing he could have done, that too with almost zero cost for the raw material

PRODUCTS

The very first product that he developed out of chicken feathers was a paint brush. It was just a hit & trial method that went right. Being a protein fiber, its water absorbency is very high. I was able to work 10 times more with one dip of color in comparison to any paint brush found in the market, he said. Later, he went on to work with various kinds of products. The Feather wool yarn is given to Tribal women and artisans (trained by his organization) to make a variety of wearable items ( from their home or workshops ) like running Cloth, Quilt, Shawls, Jackets, Embroidery, Stoles, and Mufflers. The by-product from their process is scientifically converted into compost and distributed to local farmers as Fertilizer. The cost of Feather wool thread is very low as it is extracted from garbage hence can compete against regular wool, cotton and synthetic fiber based apparels.

AWARDS & RECOGNISATION

Many awards were lined up & recognition was given by the time he finished his waste to product development stage. It was a decade long effort to reach out to the stage where he stands today. But he never fails to recognise the help & effort of so many people in the journey. The friends who helped with little things like books, guidance of Mr. M. P. Ranjan who has been one of the greatest design thinkers, support of Dr. Toolika Gupta in providing him the platform at ‘India Story’. He says, ‘India story’ in true sense was a platform that helped him reach many places and he never looked back since. He received German design Award (Gold in lifestyle category ), CII Design Excellence Award (For Social Impact and sustainability) , Graham Bell Award (For young scientist), Global nominee for IKEA (In top 10), Recognition from embassy as ‘The Chickenman’ and many more in the way.

THE STORY AHEAD

Life has taken some interesting turns every now & then since he started working on this project and initial six years were quite hectic, he says. But looking back makes him joyful to have reduced migration of Tribal Labors to Urban, diminish the exploitation of Tribal Women, have built community based self-help groups, Tribal women running social NGO and Skills training programmes. Their efforts have created safer drinking water and less polluted surface and underground water resources and health hazards. He always believed that – “Designing is an art that has the capacity to show our future from the knowledge of our past. And if we don’t remember our past, we can’t design for the future”- this understanding kept him motivated in his every ups & downs. He wants to work further ahead in industrial paper, polymer plastic, bio-diesel, insulators and various other materials made out of chicken feathers. It’s a long way ahead but he is confident and motivated to take the path further down the road

Hi my loved one! I wish to say that this article is amazing, nice written and include almost all significant infos. I would like to look more posts like this .

magnificent submit, very informative. I’m wondering why the other experts of this sector do not notice this. You should proceed your writing. I’m confident, you have a great readers’ base already!The Golden Feathers